Water Transfer

Riptide Energy Solutions is a leader in the water Transfer industry. We have years of experience and reliable crews working with the latest pumping technology and an extensive inventory of water transfer equipment.

What makes Riptide Energy Solutions Unique

Reliability and Service – Riptide Energy Solutions has a commitment to a company culture that focuses on performing our services beyond customer expectations, we strive to provide a high standard of performance through customer communication and pre-job planning

Equipment Performance – Riptide Energy Solutions is dedicated to providing the latest technology and equipment in water transfer, we invest in our R and D department and continually improve our systems and equipment based on the feedback from our field personnel.

Environmental Impact – Riptide Energy Solutions understands the importance of our surrounding environment, and it is our policy to ensure every project is done with the highest standard of environmental protection and care.

Project Management & Engineering

Riptide Energy Solutions experience in water management projects includes, Oil and Gas, HDD fluid support, Mine dewatering, Municipal water management, and much more. Our team is able to help in the design and execution of any water management project, this includes selecting the right equipment for the job, designing storage volumes needed, and management of installation for both temporary and permanent projects.

Project Management – Right from the design stage, to the execution of the project, we can assist in completing projects on time and within budget.

Water Sourcing and Permitting – Riptide Energy Solutions can assist our clients with sourcing water for their upcoming projects, this includes getting access agreements in place and getting permits for water use.

Automation Controls – Using our Geodesic system, we can automate existing facility’s and water hubs, this includes tank level management, and transfer pump automation.

Containment

Riptide Energy Solutions is committed to keeping our environment clean and protected. We are proud of our Full Site and Secondary Containment solutions. We provide our customers with security and peace of mind when it comes to environmental protection by employing containment technicians that are well trained not only the materials we use, but also the service we provide, ensuring our customers receive the top-notch service they deserve.

We provide our customers security and peace of mind when it comes to environmental protection by employing containment technicians that are well versed not only the materials we use, but also the service we provide. Through our proactive approach and using the best containment materials available on the market today we can ensure our customers receive the top - notch service they deserve.

Primary – Full Site Containment for Drilling and Completions

Secondary Spill Containment for misc. Drilling or Completions equipment

Tank Containments – Individual or Tank Batteries

Duck Pond Containments

Production Containments

Full Site clean-up and liner removal

Geodesic

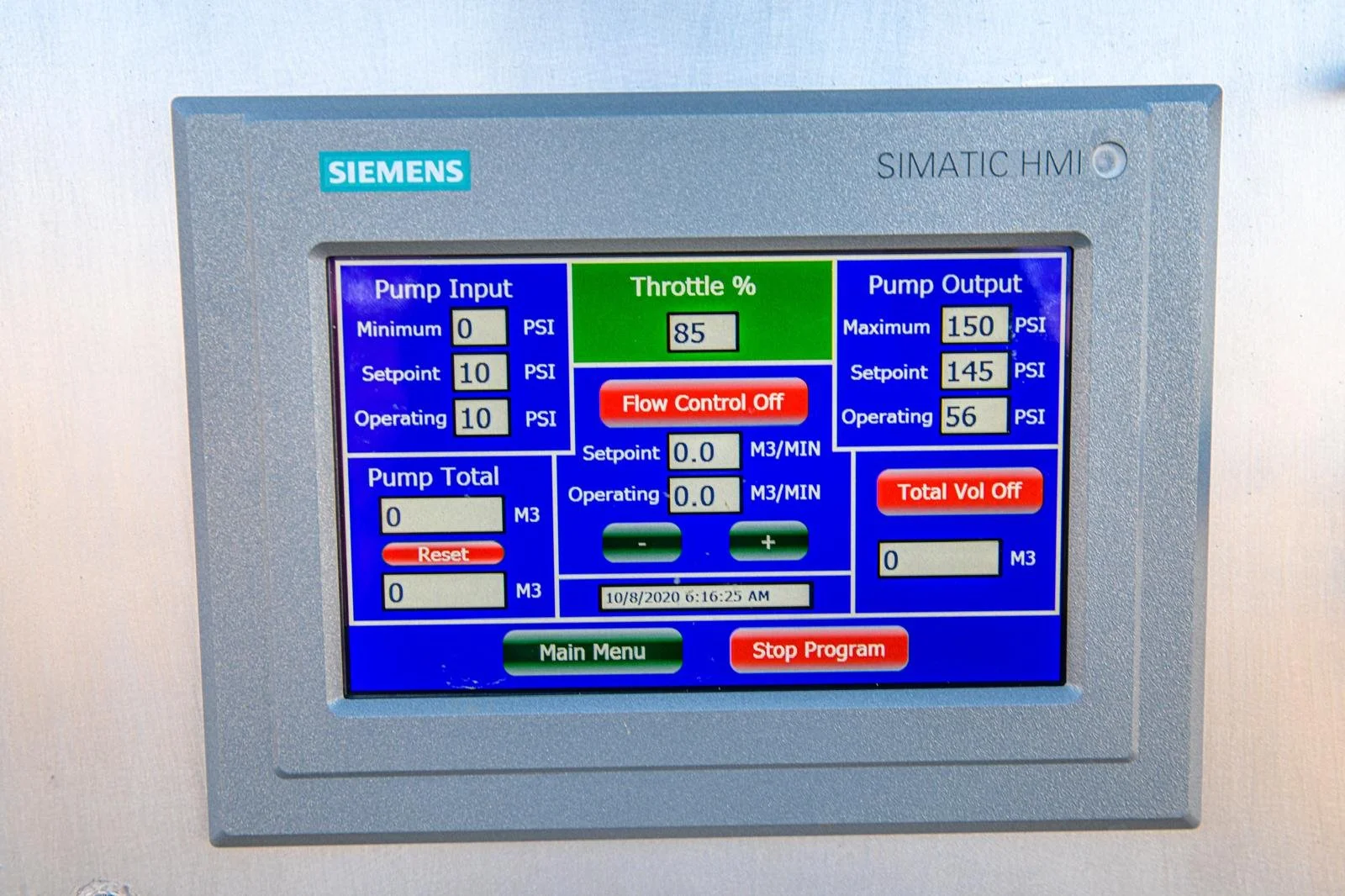

Fully Automated Pumping – Allows for a fully automated system, reducing workload while maintaining superior function.

Radio Mesh Capability – The GPM control uses a mesh radio network to communicate with a remote operator station. This network will establish itself automatically by connecting to any nearby radio to establish a complete and robust network.

On/Offsite Monitoring Capability – Operators can access this network from a control station or with a mobile device that is within range of any pump. The network allows operators to remotely monitor and control all pumps connected to the network. The network is local and does not require any subscriptions to LTE or Satellite providers to operate. The control station can be connected to an LTE or Satellite network to allow offsite access to all GPM controls connected to the local mesh network.

Logging Capability – The GPM controller can also totalize flow and output current flow rate. The GPM controller has the ability to log total volume and current flow at ten minute intervals on a flash drive, operators can also remotely monitor these perimeters.